GJ WORKING PRINCIPLE

Integrate mixing, emulsification, homogenization, dissolution, crushing and other functions Effectively improve the emulsification efficiency,save mixing time and reduce the waste of raw materials

Product introduction

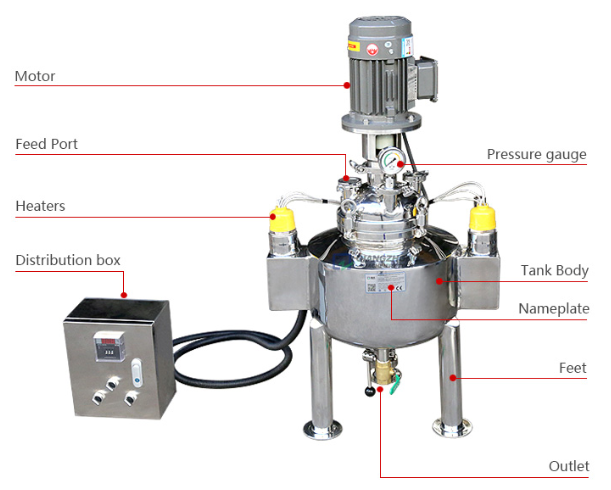

The equipment can realize the process of material dispersion, emulsification, homogenization and mixing under vacuum or pressure environment. It consists of a homogeneous mixer, central blade mixing and wall scraping mixing. They each have different characteristics, complement each other, and combine to form the best mixing method, which can perfectly mix the materials to produce high-quality products with rich luster, fineness and good ductility. The function of the emulsification tank is to dissolve one or more materials (water-soluble solid phase, liquid phase or jelly, etc.) in another liquid phase and hydrate it into a relatively stable emulsion. In particular, it has a good dissolving and emulsifying effect on sugar, milk powder, and gum additives in production, and it is currently the most efficient product among similar products. But sometimes for different materials and working conditions, a single emulsifying machine in the emulsifying tank often cannot meet the production requirements. At this time, it needs to be equipped with other agitators to assist the emulsifier mixing to achieve better mixing effect.

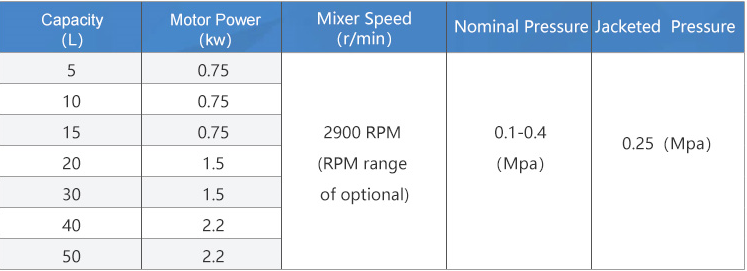

GJ PRODUCT PARAMETERS

Technical file support: random provide equipment drawings (CAD), the installation drawing, the product quality certificate, installation and operating instructions, etc.