Electric Heating Fermentation Tank

Widely used in industries of brewery, dairy products, beverage, daily chemicals, bio-pharmaceuticals, etc. Mix, disperse, emulsify, homogenize, transport, batch......

| Designed Pressure | 0.02MPa 〜I .OMPa |

| Designed Temperature | Customization is acceptable |

| Treatment | Mechanical polishing, sandblasting, pickling |

| Polishing Accuracy | Inner Wall 0.4pm, Outer Wall 0.6pm |

| Inner Body | 304,316L |

| Insulation | Rock Wool or Polyurethane |

| Feet | 304 |

| Inlet & Outlet | Quick Chuck Interface, Flange |

| Capacity(L) | Diameter (mm) | Height(mm) | Motor Power (kw) | Mixing Speed (r/min) |

| 50 | 300 | 650 | 0.37 | 60 (Oblique Blade Paddle) (Could be customized) |

| 100 | 400 | 800 | 0.37 | |

| 200 | 550 | 900 | 0.55 | |

| 300 | 600 | 1000 | 0.75 | |

| 400 | 700 | 1100 | 0.75 | |

| 500 | 750 | 1200 | 1.1 |

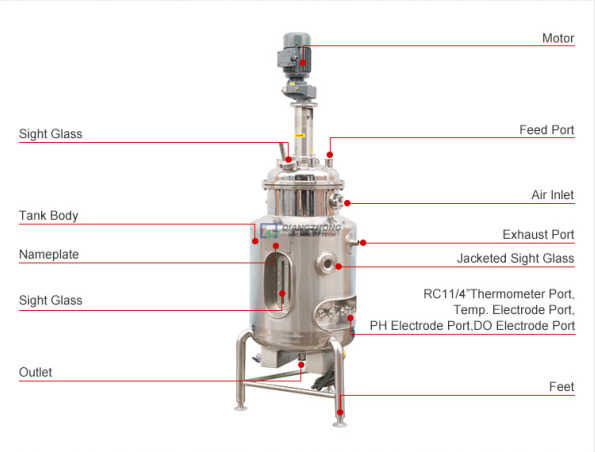

Biological fermentation tank adopts a vertical circular tank body, the upper part is a standard oval or dish-shaped head, and the lower part is a standard oval head, dish-shaped head or conical head. The internal wall transitions of the tank body adopt a circular arc transition no health dead corner and easy to clean. The jacket structure can be designed according to customer needs (tank body and lower head with a jacket and insulation), the top could be configured with mechanical stirrers.

Optional Configuration

Aseptic air filter, thermometer (digital or dial type), PH meter, pressure gauge, steam sterilization port, sight glass, sanitary hole, inlet and outlet hole, CIP swivel ball, level gauge and Liquid level automatic control system (load-bearing module, non-contact ultrasonic, static pressure transmission device), etc., or configured according to customer requirements.

Typical Application

Suitable for fermentation in the fields of medicines, biological products, dairy products, foods, wine, beverages, personal care products, etc.

Product Features

• Capacity is available from 600L to 20.000L, and also could be customized in other capacities as requested.

• The jacket can be input with either steam (or hot water) or cooling water. The jacket could be coil jacket, full jackets, and Miller plate jacket, which is covered with insulation of rock wool or polyurethane.

• With quick chuck interface, inner body is made of SUS304 or SUS316L stainless steel, inner surface is mirror-polished Ra<0.28pm~ 0.6pm. Outer surface can be polished, brushed, sandblasted or others according to customer requirements.