We specialize in manufacturing food and medical equipment, and know you better!

This product is widely used in food, beverage, pharmaceutical, bioengineering,water treatment, daily chemical, petroleum and chemical industries.

Q&A

Q1: What is the lift and flow of this pump?

A1: The lift and flow of this pump is based on motor power. You can tell us your required flow and head, our engineers will customize the motor for you.

Q2: What is the motor brand?

A2: The brand of non-explosion-proof motor is Dedong, and the explosion-proof motor brand is HuXin. If customers require other brands of motor, such as ABB, Siemens, etc., we can also customize it.

Q3: What is the connection type of the pump?

A3: There are three connection types, namely clamp connection, thread connection and flange connection. The default connection method is clamp connection.

Q4: What is concentration of the materials that can be conveyed by the pump?

A4: The highest concentration is 04 Generally, the liquid can be transported as long as it can flow automatically.

Q5: What is the maximum working temperature of the pump?

A5: The maximum working temperature is 150 degrees Celsius, and both double seals and water cooling should be used when it is above 100 degrees Celsius.

Q6: Is there any explosion-proof motor and variable frequency motor available?

A6: Yes, the explosion-proof motor or variable frequency motor is available according to customers' requirement, but the standard motor is non-explosion-proof and non-variable frequency motor.

Q7: What is the material of the pump?

A7: The standard material is 304 stainless steel, and if require 316L stainless steel please advise us before placing the order.

Q8: What is the motor voltage?

A8: The standard voltage in China is 3 phase/380v/50hz, and if any other voltage is required, please check with us before order confirmation.

INSTALLATION INSTRUCTIONS

Installation Method and Place:

It is very necessary to check the following before installation:

•The drive is in good condition.

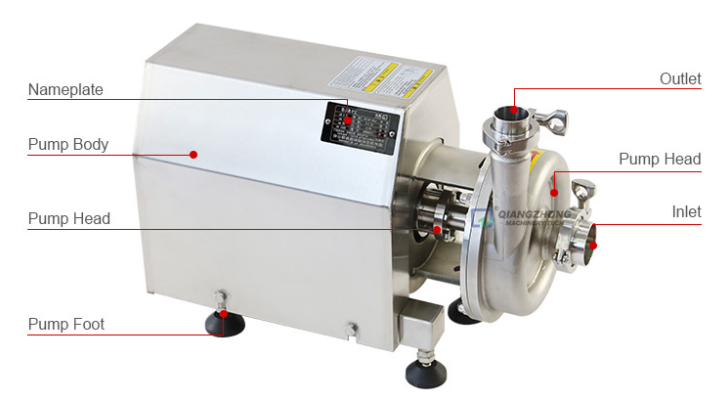

•Whether the on-site power supply is the same as the rated power on the motor nameplate.

•Whether it meets the environmental conditions (avoid flammable and explosive environment or acid corrosion environment).

Installation Location:

The installation foundation of the pump should generally be level and sufficient-strengthened ground. Install it as far as possible on the lowest position of the equipment, that is, at the position with the maximum head height.

Piping Installation:

The diameter of pump、pipe and the inlet and outlet of the pump should be the same, and the diameter of the inlet pipe should not be too small. When the diameter of the pipe is smaller than the diameter of the pump, adjust it with an eccentric reducer to shorten the diameter of the pipe so as to avoid formation of a gas leak. The outlet pipe diameter must not be too large either. When the outlet pipe diameter is larger than the pump outlet, try to extend it. Distance from the pump outlet to avoid overloading the pump motor.