| Model | Motor Power (kw) | Displacement(L) | Speed Range (r/min) | Traffic (L/H) | Diameter (mm) |

| ZB3A-3 | 0.55 | 3 | 200-500 | 300-800 | DN20 |

| ZB3A-6 | 0.75 | 6 | 200-500 | 650-1600 | DN20 |

| ZB3A-8 | 1.5 | 8 | 200-500 | 850-2160 | DN40 |

| ZB3A-12 | 2.2 | 12 | 200-500 | 1300-3200 | DN40 |

| ZB3A-20 | 3 | 20 | 200-500 | 2100-5400 | DN50 |

| ZB3A-30 | 4 | 30 | 200-500 | 3200-6400 | DN50 |

| ZB3A-36 | 4 | 36 | 200-400 | 3800-7600 | DN65 |

| ZB3A-52 | 5.5 | 52 | 200-400 | 5600-11000 | DN80 |

| ZB3A-66 | 7.5 | 70 | 200-400 | 7100-14000 | DN65 |

| ZB3A-78 | 7.5 | 78 | 200-400 | 9000-18000 | DN80 |

| ZB3A-100 | 11 | 100 | 200-400 | 11000-21600 | DN80 |

| ZB3A-135 | 15 | 135 | 200-400 | 15000-30000 | DN80 |

| ZB3A-160 | 18.5 | 160 | 200-400 | 17000-34000 | DN80 |

| ZB3A-200 | 22 | 200 | 200-400 | 21600-43000 | DN80 |

| ZB3A-300 | 30 | 300 | 200-400 | 31600-63000 | DN100 |

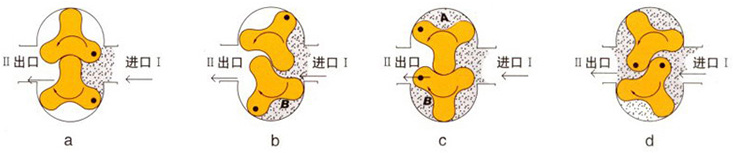

WORKING PRINCIPLE

The rotor pump is also called colloid pump, tri-lobe pump, shoe sole pump, etc. It relies on two synchronous and counter-rotating rotors (normally 2-4 teeth) to generate suction (vacuum) at the inlet during the rotation to suck the material.

The rotors divide the rotor chamber into several small spaces and runs in the order of a—b-*c—d. When running to position a, only chamber I is filled with medium;

When it reaches position b, part of the medium is closed in chamber B;

When it reaches position c, the medium is also closed in chamber A;

When it reaches position d, chambers A and B are connected to chamber II, and the medium is transported to the discharge port.

In this way, the medium is continuously transported out.

The lobe pump is a multi-purpose transfer pump which adopts two-lobe, tri-lobe, butterfly or multi-lobe rotor. As a sanitary volumetric delivery pump, it has the characteristics of low speed, high output torque, high temperature resistance, corrosion resistance, etc. Its unique working principle and characteristics are embodied in conveying high viscosity, high temperature, and highly corrosive materials. Its conveying process is smooth and continuous, and it can ensure that the physical properties of the materials are not broken during the conveying process, and the viscosity of the conveyable materials can be up to 1,000,000 CP.

APPLICATION CHARACTERISTICS

APPLICATION CHARACTERISTICS

High Viscosity Material Transfer Pump As a positive displacement pump, it has low speed, high output torque and high temperature resistance, making it especially suitable for conveying high viscosity and high temperature materials. Its unique working principle combined with a powerful drive system ensures that the rotor pump can output a powerful drive torque at low speeds. It is ensured that the material is conveyed continuously and without stagnation, and that the properties of the material are not destroyed during the conveying process. The pump can deliver media with viscosities up to 1000000CP.

Thin Media Transfer Pump Rotor pumps have a comparative advantage when transporting particularly thin media, especially when it is required to output a thin medium without pulsation. The drive system equipped with the rotor pump can operate at a higher rotational speed when the viscosity of the medium to be transported decreases, and the leakage amount increases, ensuring a constant output flow rate.

Sanitary Transfer Pump All parts in contact with the material are made of stainless steel that meets hygienic standards. It is suitable for all sanitary and corrosion resistant applications and is widely used in food, beverage, pharmaceutical, chemical and other industries.

With Insulation Jacket Depending on the needs of the different work spaces, an insulation jacket can be added to the rotor pump. This structure can ensure that the material which is easy to solidify at a low temperature state is kept at a constant temperature during the transportation process, and no condensation occurs.

Water Flushing Mechanical Seal A mechanical seal structure with water flushing function can be provided to prevent material from condensing on the end face of the mechanical seal during the process of conveying high-viscosity materials, thereby affecting the normal operation of the equipment and ensuring the use of mechanical seals in harsh environments. life.